Gas Assisted Moulding

Cost Benefits

The potential benefits of gas assisted moulding can be split into two categories, cost and design.

Cost

- Reduced cycle time

- Reduced weight

- Clamp tonnage reduction

- Energy Savings

Design

- Thick sections can be combined with thin sections

- Hollow structures can be produced

- Box beam structures for stiffness and rigidity

- Class ‘A’ surface finish

- Reduced internal stresses

- Dimensional stability

Short Shot Moulding

The mould cavity is only partially filled with plastic (70-95%) and Nitrogen gas is used to complete the mould filling with plastic and replace plastic packing with gas packing.

Full Shot Moulding

The mould cavity is completely filled and packed with plastic and Nitrogen gas is only used to assist with additional packing during part cooling

PEP (Overspill)

Similar to the Full Shot process, but as Nitrogen gas is injected, a valve is opened inside the tool to allow plastic to be displaced by the gas into an “overspill” cavity resulting in a “high hollow” core out.

External Gas Moulding

In this process, Nitrogen Gas is applied to the “B” surface of the part through the core side of the mould to push the (still molten) plastic against the “A” surface of the mould tool.

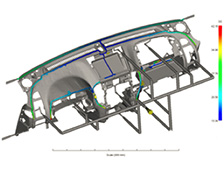

State of the art software

Cinpres UK Limited’s Design Engineering personnel can offer detailed plastic filling, plastic packing, Gas filling and Gas packing analyses using state of the art Moldex 3D software

Spares

Wide range of spares available.

Contact us to find out more

Experience

Cinpres UK Limited Engineers have some of the industry’s longest experience